Today’s globalized supply chain is no longer a simple linear chain, but rather a complex, demand-driven network spanning different countries around the world. With complexity new challenges arise and the need to diagnose and overcome these challenges. There are various obstacles such as monitoring the environmental conditions and the location of shipments, ensuring the safety of products in transit, fulfilling customer expectations by delivering on time while managing the right level of inventory and safety stock. Explained below are few of the problems in supply chain that ‘demand’ supply chain visibility.

1: Business Inefficiency

With numerous moving parts across the world and different partners and suppliers involved, a single shipment, for example, has over 200 interactions with more than 25 people along its way from source to destination. According to resources, only 6% of businesses currently have complete visibility into their supply chain, which means for the majority of companies, these interactions are going unmonitored and untracked. The unavailability of real-time data creates siloes along the demand fulfilment process and is directly causing business inefficiency. To put this in figures, in UK alone, more than 100 million hours of time are wasted per year in procurement, supplier management and freight-administration functions for a total annual cost of £1.5 billion ($1.98 billion). Such inefficiencies can be easily eradicated if the real-time data is available throughout the shipping process. Moreover, real-time updates from shipments enable you to change your approach from being reactive, relying on contingency-based planning to being proactive, strategic, and equipped to make informed cost-effective decisions. The result is no less than increased revenue, reduced fees, and more control over cash flow.

2: Unpredicted disruptions

While no company hopes for a supply chain breakdown, every business needs to plan for one to minimize uncertainties. From a weather-related event to a geopolitical event, supplier bankruptcy or dockworkers’ strike, no supply chain is safe from unexpected supply chain disruptions. For e.g. a late shipment due to unfavorable weather conditions in the Caribbean or unreported delays by logistics service providers can have a ripple effect on the productivity of the entire supply chain. A factory might need to either stand idle or ramp up a production line to compensate; a retailer may have to work around an inventory shortage on store shelves; or a distributor may need to adjust staffing on its loading docks to account for both unproductive time and for personnel adjustments when a shipment finally arrives. But with careful planning and forward-looking visibility, a business can have contingencies in place for any disruptions that might occur. Reliable supply chain visibility can lead to more accurate forecasting, which results in better inventory control.

3: Loss of product integrity

One of the challenges which arise with the lack of supply chain visibility is that businesses risk the integrity of their products as they travel thousands of miles from suppliers to a distributer, up until they reach the end user. This is a major challenge for food products as compliance with their safety, quality, legality, and product authenticity are of paramount importance for all food industry experts. In addition to food products, maintaining integrity is important for other goods in transit that are fragile, sensitive or perishable. Maintaining environmental conditions for these goods at optimal levels is paramount to reducing costs or waste, as well as possibly avoiding risking public health in the case of shipping pharmaceuticals. Industries like pharma and healthcare have regulatory compliances that companies need to follow, posing additional challenges if they cannot guarantee the safety of products throughout the shipping process.

4: Unavailability of reliable data

Data empowers supply chain visibility and without it an organization cannot gather accurate insights into their global operations to get rid of problems in the supply chain. Real-time data about the location and condition of products in transit plays an important role in creating a balanced and efficient supply chain. Over the years, many companies have invested significant amounts of money to address supply chain challenges, yet most of them are still searching for a better option. When it comes to freight visibility for example, most of the organizations have limited access to data, they are only notified when their shipments reach checkpoints, such as a seaport, but they don’t know their products’ locations and condition while they are in transit. If a certain part of a product gets damaged or lost in transit, it may be extremely difficult to know where and when the damage took place. Missing transparency along with unreliable real-time data into the supply chain introduces risk factors in ensuring product compliance, understanding demand and capacity, and assessing diagnostics to the disruptions. Right supply chain visibility solution enables real time information-sharing, better risk anticipation, enhanced flexibility, extended degree of control over processes, better collaboration and decision-making as well as higher profitability.

5:Increasing supply chain risks

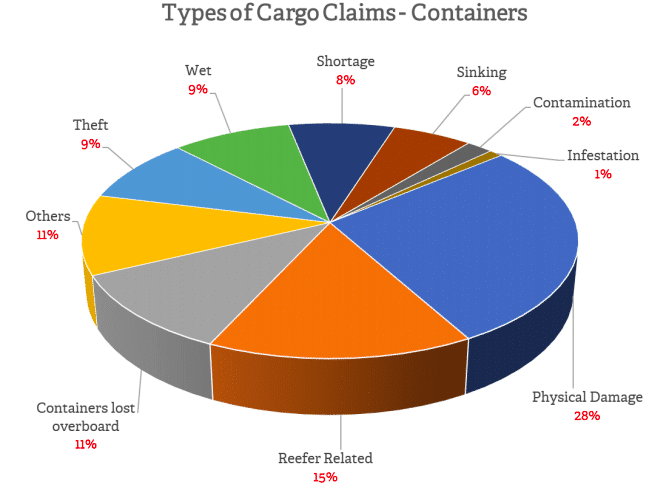

Risk results from any form of uncertainty in a process or in the environment and so is the case when it comes to risks within the supply chain ecosystem. The potential risks cargo can be exposed to is versatile and includes delivery delays, food spoilage, poor packaging, improper cargo handling, production halts, unanticipated demand surge, inventory management, infrastructure outages, cargo theft, increased demurrage and detention charges, cargo burning on board of the vessel, cargo falling off from the vessel or washed on shore, sustainability, administration inefficiencies etc. With reliable IoT enabled supply chain visibility solutions, manufacturers can identify potential risks and mitigate these challenges as they arise. Visibility provides detailed insights and fosters improved risk management allowing companies to forecast what may happen within their supply chains and how they can manage such events before they cause disastrous consequences causing several other problems in the supply chain. Manufacturers and shippers won’t have to rely on stale data and can be more proactive in response to any disruptions.

How can Arviem help you achieve Supply Chain Visibility and mitigate risks?

Arviem’s supply chain visibility solution support their users in the efficient management of strategic, operative and financial supply chains via enabling real-time data-driven decision making to solves prevailing problems in the supply chain . The installed automated locating and sensing technology on multimodal containers and cargo addresses the need of decision makers for end-to-end, timely, quality data. Arviem offers a wide array of services that are transforming supply chains by combining the latest sensor technology, big data, and clever data analytics methodology with easy integration to your current system. Arviem’s cloud-based infrastructure and supply chain visibility software is an enabler for the transformation of the collected data into actionable information. Are you looking to drive out costs, inefficiencies and waste from your supply and logistics chain with increased visibility? Learn HERE or request a personal demo here.