The evolution of technology in all the industries including the food supply chain is pushing the boundaries of digitalization and has changed our day-to-day lives in all aspects. Did you think years ago that you would be able to turn on your ceiling fan from your smartphone? A world where a computer drives you from Point A to Point B or you receive a package from a flying unmanned aerial device sounds like something out of a movie, but that is real and that is where we are heading. With all of the fast-paced revolutions, technology is changing every aspect of our lives, constantly striving to make it easier, faster, better and more fun.

Technology advancements in the logistics and supply chain industry has not stayed behind in the race. The transportation and logistics industry have traditionally been defined by trucks and infrastructure, but over the past several years technology has begun to change the way business is done. Due to the advancements in technology, the supply chain is more transparent than ever before, and businesses have become digitally connected including down to the level of end users. From robotics in warehouses to computerized shipping and tracking, technology has changed the industry for the better and has provided new levels of visibility.

Unlike every other industry, food and beverage supply chain has a unique role in ever growing economy because it is universal to human life and health. Food and beverage industry is a fast-paced multi-billion-dollar industry that is excessively driven by human population. According to the United Nations, food production would need to grow by as much as 70% from 2010 to 2050 to meet the needs of 9.7 billion people by the end of 2050. This growth in the food and beverage industry is accompanied with manifold challenges driven by changing global trends. Globalization, safety, regulation, efficiency, and refrigerants are now leading variables in food supply chain management. New and emerging technologies are introducing faster, safer and more intelligent ways to design, optimize and manage the food supply chain.

Here are a few food supply chain trends that you should know if you are dealing with food logistics:

Demand for food safety and security: Ensuring the quality of food and food security is the topmost requirement of consumers when it comes to the food and beverage supply chain. Ensuring quality requires far more than simply loading goods into a refrigerated container, adjusting the temperature settings and loading it onto a container ship. An end to end visibility into the global supply chain is absolutely required to ensure that the products are not deteriorated in quality during the whole journey. Even a single area of weakness within the global supply chain can compromise food safety resulting in significant brand and reputational damage to the supplier. Moreover, food security within the supply chain is critically important as the traded products are consumed by humans which can impose significant threats to human life. Security becomes even more important as the companies need to adhere to emerging rules and regulations. Ensuring regulatory compliance and preventing contaminated food products that result in waste and recalls is an unavoidable challenge for food and beverage supply chain and would be a top priority for seeking technological advancement. A key methodology to food safety compliance is track and trace, which has the ability to track food through the entire food supply chain from farm to table. Read more here and here!

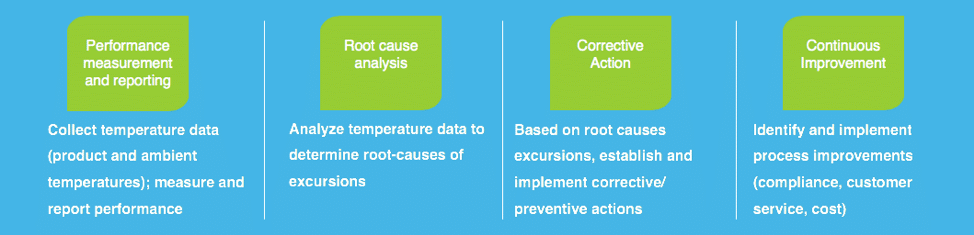

Cold Chain Management: Cold-chain management is an essential aspect of many food and beverage operations today. The basic steps involved in cold chain management can be well understood by following graphics:

Cold Chain Management

Undoubtedly, cold chain management has entered a brave new world characterized by sophisticated temperature tracking and monitoring with the help of technologies like IoT (Internet of Things). To put this in figures, the cold-chain market is huge and growing. The global cold-chain market is projected to reach a value of $271.30 billion by 2022 with a CAGR of 7.0%, according to the “Cold Chain Market, Global Forecast to 2022” report issued by Markets and Markets. The projected increase can be attributed to the growth of international trade of perishable foods, increased consumer demand for high quality perishable food products, technological advances in refrigerated storage and transport, spurred on by movements to deliver goods even faster to consumers while accommodating even stricter regulations will make cold chain management a must have for global supply chains. Read more here!

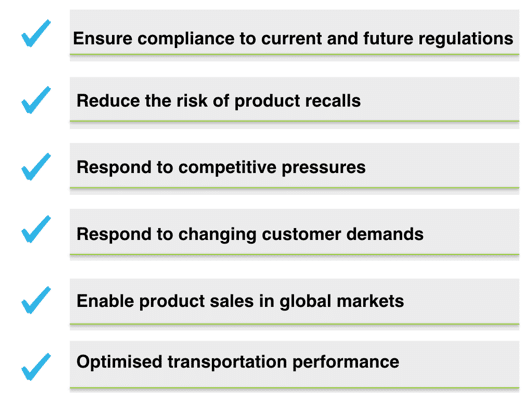

Predictive Analytics: Predictive Analytics enables real-time decision making and forward planning on both strategy and performance. The ability to be proactive and anticipating the future will make predictive analysis the next big thing in supply chain business intelligence. Improving forecast accuracy, optimizing transportation performance, improving product tracking & traceability and analyzing product returns are the use cases with the greatest potential for analytics growth within the supply chain. In addition to the application of analytics in tracking and tracing, the second application of food supply chain analytics is in non-real time. Data from supply chain operations are accumulated in a central database that various supply chain stakeholders can access. This ensures that everyone is using the same data and that reporting is consistent. In this environment, user dashboards, reports and custom queries can be developed. They can tell you if you’re spending too much of your transportation dollars for food transport on a given route, or whether that last lettuce shipment is in danger of spoiling as it makes its way to Atlanta. Thus, Real-time and predictive analytics are crucial components to successful supply chain management, but for the food supply chain, it is mission critical and can accomplish the following checklist as agreed by many supply chain professionals:

Benefits of Predictive Analytics

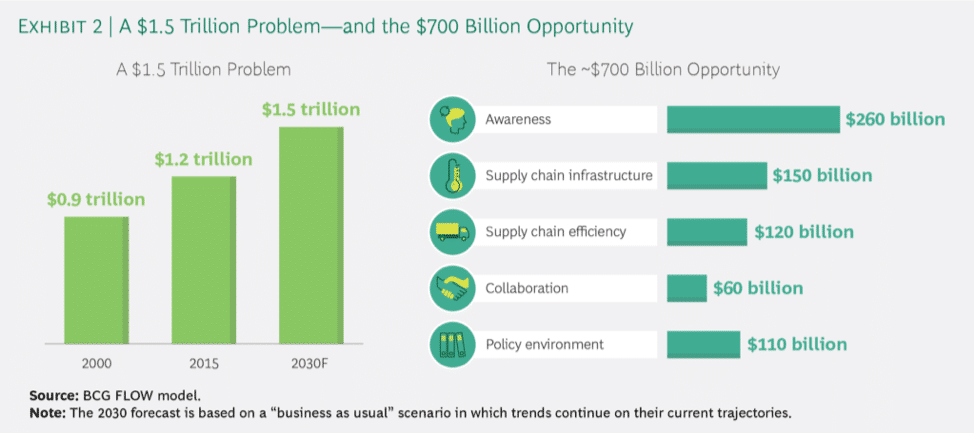

Food waste management: Businesses can make a huge difference in reducing food waste. According to the FAO data, one-third of food produced for human consumption is lost or wasted globally, which amounts to about 1.3 billion tons per year. World Resources Institute also indicates that throughout the entire supply chain, food worth $750 billion is either lost or wasted each year. The food waste in the transition mainly occurs due to poor transportation networks, lack of preservation techniques, improper temperature and humidity conditions, unplanned longer routes and delays in transit. With the globalization, the global food supply continues to grow in volume and complexity thus the supply chain in the food industry needs special attention to minimize food waste. To put this in figure, A $1.5trillion problem puts forth $700 billion opportunity of which the maximum is focused on optimizing the supply chain.

Food Waste Problem

Efficient food supply for socioeconomic progress: Around one-third of the food that is produced globally is wasted — either spoilt in transit or thrown out by consumers in rather wealthier economies. This waste results in at least 1.3 billion tons of annual food loss, nearly $1 trillion worth in retail prices as stated by National Geographic. This large amount of food wastage significantly affects the environment as well. The carbon footprint of food waste is estimated to be 3.3 Gigaton of carbon dioxide. This makes up approximately 7% of all global emissions as published by the United Nations’ Food and Agriculture Organization (FAO). The poor transportation networks, the lack of preservation techniques, or improper temperature and humidity conditions can cause the spoilage during transportation. Distribution and transportation of food have been one of the major causes of greenhouse gas emissions. Therefore, wasting food not only means that resources are wasted but the greenhouse gas emissions that it emits also has dangerous effects and would be one of the major focus areas towards socio-economic progress. Read more here!

How Arviem can help you implement the best practices mentioned?

Arviem AG provides supply chain visibility solution which helps companies to take proactive measures towards efficient transit of perishable products. Arviem’s supply chain visibility and real-time cargo monitoring reveals what’s happening to the cargo while in transit. Arviem provides real-time, trustworthy and carrier independent data about the whole journey of the goods from the point of manufacture to the point of delivery uncovering supply chain blind spots. The collected real-time data provides insights for decision makers to review and optimize supply chain operations and to uncover inefficiencies and costs. Besides optimized shipping costs, supply chain visibility solutions also allow its stakeholders to mitigate the inherent risks of a global food supply chain ensuring early detection of deteriorated food quality and availability. This, in turn, maximises the product quality and optimises shelf life of products.

Arviem offers full range of services from setting up of IoT enabled cargo tracking device to providing reverse logistics after completion of shipment. Arviem provides cloud-based software equipped with required business rules. We are the only service provider offering pay-per use real-time monitoring services without the need for investing into new technologies, hardware or other resources. Arviem’s agile service also works alongside legacy systems making integration with clients’ systems possible via an API. This helps companies to implement cost-effective, advanced and innovative functionalities to their systems without the need for in-house development.