Reduce Inventory and Achieve Supply Chain Efficiencies

Holding excess inventory is costly and also negatively affecting the efficiency of the supply chain. High inventory levels pile up to overcompensate for uncertainty in the absence of accurate data in the extended supply chain. Data through visibility creates transparency in supply chains leading to reduced inventory and efficiencies.

Reduce inventory levels, by making information on the whereabouts of inventory readily available to all stakeholders in the supply chain

Use real-time and historical data to create leaner supply chains by better managing and controlling in-transit inventory

Arviem’s cargo monitoring provides supply chain visibility to reveal hidden bottlenecks. Challenging these bottlenecks through continuous improvement initiatives creates efficiencies such as shorter lead-times, reduced demurrage and expediting costs. Furthermore, the gained accurate independent data, builds stakeholder trust throughout the supply chain reducing the tendency for stakeholders to overcompensate leading to reduced inventory levels

You can optimize even more

Read more:

Identify bottlenecks

Use supply chain analytics and data-driven management reports to reveal bottlenecks. Analytics permits supply chain stakeholders to understand and challenge the root cause of previously hidden and known inefficiencies.

Eliminate information silos and build trust

Independent visibility of global supply chains eliminates information silos, enables all stakeholders to share trusted data to improve overall performance and share gained efficiencies, to deliver greater value and ROI.

Reduce overcompensation

Failure of a supply chain to deliver on time and in full encourages stakeholders to buffer stock, just in case! This simple action has a detrimental impact not alone on inventory levels, but the associated costs of storage, stock control, insurance, manufacturing, raw materials, quality assurance, damage, etc.

Encourage a culture of continuous improvements

Visibility enables the natural inquisitive mind to question inefficiencies in the belief that there must be a better way. Through continuous incremental improvements in each segment of a supply chain, the overall performance is enhanced to deliver greater customer value.

Take immediate corrective action

Establish central event management for all product moves. Timely alerts of potential risks to cargo permit immediate corrective actions to be instigated. This appropriate intervention reduces the possible knock-on effects of quality, non-compliance, and customer dissatisfaction.

Reduce variability

Reduce variability by relying on predictive ETAs to identify and eliminate delays before they become problems.

Be SMART (Specific, Measurable, Attainable, Relevant and Time-bound)

Accurate, independent data empowers stakeholders to define route-specific benchmarks, that are measurable, attainable, relevant, and time-bound. These strategic KPIs deliver real customer value.

Identify bottlenecks

Use supply chain analytics and data-driven management reports to reveal bottlenecks. Analytics permits supply chain stakeholders to understand and challenge the root cause of previously hidden and known inefficiencies.

Eliminate information silos and build trust

Independent visibility of global supply chains eliminates information silos, enables all stakeholders to share trusted data to improve overall performance and share gained efficiencies, to deliver greater value and ROI.

Reduce overcompensation

Failure of a supply chain to deliver on time and in full encourages stakeholders to buffer stock, just in case! This simple action has a detrimental impact not alone on inventory levels, but the associated costs of storage, stock control, insurance, manufacturing, raw materials, quality assurance, damage, etc.

Encourage a culture of continuous improvements

Visibility enables the natural inquisitive mind to question inefficiencies in the belief that there must be a better way. Through continuous incremental improvements in each segment of a supply chain, the overall performance is enhanced to deliver greater customer value.

Take immediate corrective action

Establish central event management for all product moves. Timely alerts of potential risks to cargo permit immediate corrective actions to be instigated. This appropriate intervention reduces the possible knock-on effects of quality, non-compliance, and customer dissatisfaction.

Reduce variability

Reduce variability by relying on predictive ETAs to identify and eliminate delays before they become problems.

Be SMART (Specific, Measurable, Attainable, Relevant and Time-bound

Accurate, independent data empowers stakeholders to define route-specific benchmarks, that are measurable, attainable, relevant, and time-bound. These strategic KPIs deliver real customer value.

We provide fully managed, care-free cargo monitoring and supply chain visibility services. We increase the transparency in global supply chains by collecting data with IoT enabled sensor devices attached to cargo shipments.

We provide highly accurate data, analytics and notifications on the flow of goods in transit. Our globally operating operations team takes care of your cargo monitoring needs in real-time 24/7.

We bring real value to your business operations. We help you to leverage increased supply chain visibility to reduce your demurrage costs and increase the efficiency of your supply chain.

A complete cargo monitoring service

consisting of three components

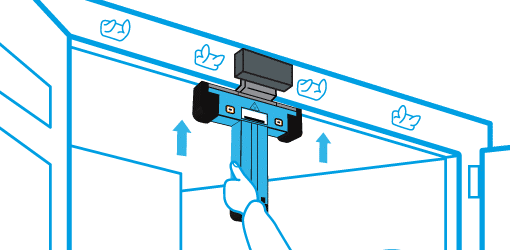

Data through monitoring devices

Monitoring devices are attached to the cargo at the point of loading and collect information while the cargo is in transit. They transmit data in real-time to the analytics platform. Devices measure humidity, temperature, light, shock and GPS location.

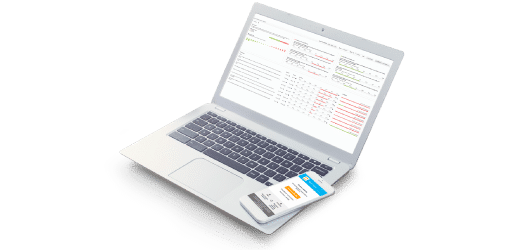

Data analytics and notifications

In case of disruptions, notifications with actionable information are provided to clients. To support the decision-making process, Arviem’s data analytics platform provides both a quick picture on the cargo in transit and in-depth analyses and visualization of the supply chain helping to uncover inefficiencies and logistics blind spots.

Global device operations

To ensure a carefree service to the client, device logistics, maintenance, repair and reverse logistics are handled by the operations team as well as client support and the initial project set-up.

Start reducing inventory with Arviem!

Reach out to us by filling out this form and we will be in touch with you to arrange a call or to set up a demo.

ARVIEM

Arviem solves the challenges of obtaining visible and intelligent trade by offering real-time end-to-end cargo monitoring services. As the only full-service provider for real-time cargo monitoring on the market, Arviem provides exceptionally accurate location and quality condition monitoring of cargo throughout the global supply chain. Our leading-edge solution will provide global supply chain stakeholders with on-demand access to real-time, transport-related data.

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 885924

© 2023 ARVIEM AG

VISIT US!

Haldenstrasse 5, 6340, Baar, Switzerland

CONTACT US

info (at) arviem.com

FOLLOW US ON SOCIAL MEDIA