Are your CRM and ERP systems sufficient to make sure that products reach their destination efficiently and in perfect quality?Are they enough to give you needed supply chain visibility?

Gone are the days when managing the global supply chain was linear and simple. Ever expanding amount of data, people, processes and technology has given rise to complexities in the marketplace. Sharing information within complex global supply networks with all the tiers of the supply chain, as well as tracking and tracing the goods, is getting more and more difficult to manage. This view is also supported by industry professionals. According to a report by Geodis 2017 Supply Chain Worldwide, a survey of 623 supply chain professionals in 17 countries, 70% of firms described their supply chain as “very” or “extremely complex”, 74% said they use four to five different transportation modes in their supply chain. These figures clearly state how extensive and complex the global supply chain is becoming. Supply chain visibility can be the answer to the newly arising complexities.

Here are the seven most important reasons why supply chain visibility along global supply chains is more important than ever before:

1. Increasing loses from supply chain disruptions

In recent years, the severity and frequency of supply chain disruptions seems to be increasing. According to a report by World Economic forum, significant supply chain disruptions reduce the share price of affected companies by as much as 7% on an average. The report also tells that 80% of companies worldwide prioritize improvement in supply chain security. One of the top reasons for many companies for the increase in supply chain disruptions is lack of adequate visibility over their supply chain. The lack of supply chain visibility has negative impact on companies; it leads to loss of productivity, increased cost of working capital as well as damage to brand reputation. To prevent such losses, organizations are in immediate need of transparency within the supply chain.

Learn more about Logistics and Supply Chain Optimization here!2. Changing customer expectations

Thanks to the growing competition within the marketplace, every individual has increasing options of products to consume. Every individual and company demands better and faster service. Increased options give the clients the liberty to demand more. Clients are now intolerant to the late deliveries or the deteriorated quality of products after transport. This eventually leads to loss of customers as they can quickly find better alternatives. To meet the rising demand of customers, companies need a transparent supply chain with better flow of data and information. This helps in preventing order errors and in turn add to customer satisfaction. With end to end supply chain visibility, information can be made readily available to all stakeholders, the demand can be reshaped, and supply in-transit can be redirected whenever and however necessary.

3. Globalisation of supply chain management

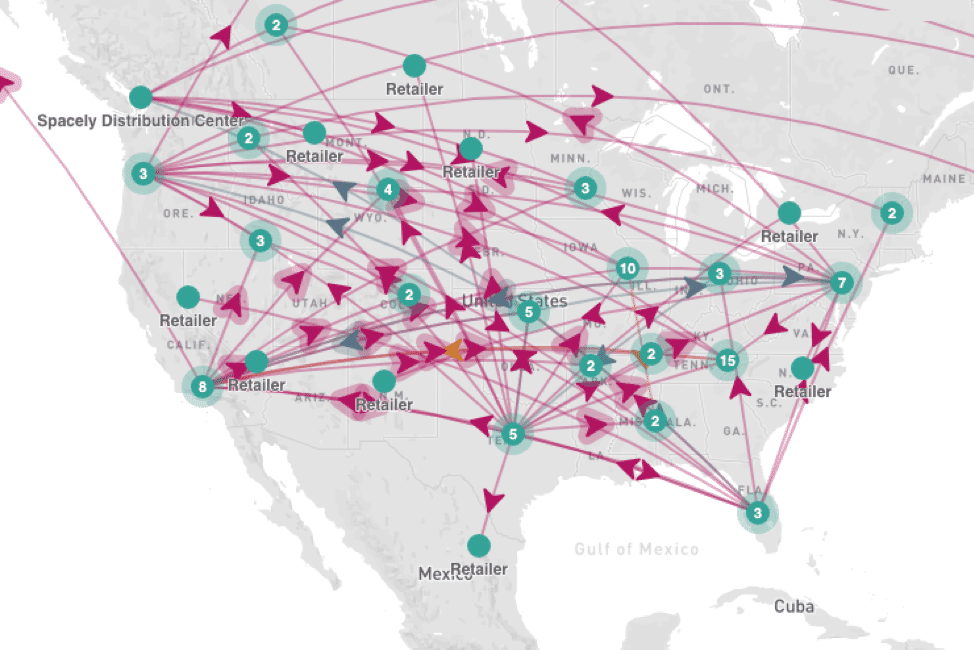

In our global ever-expanding economy, supply chains are often spread across countries., regions and continents. For e.g. the extensiveness of supply chain only in the region of North America can be seen below.

Supply Chain Globalization (Reference: OpensourceMap)

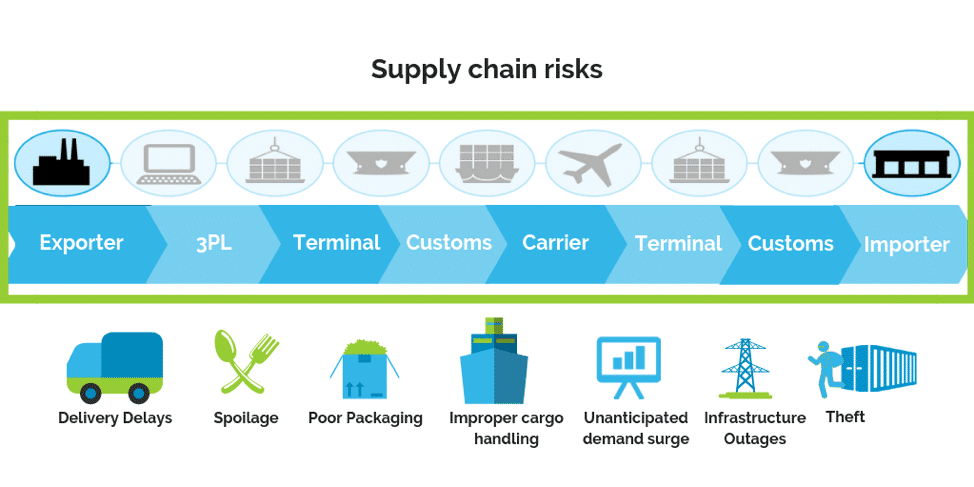

As a result, companies may have difficulties in overseeing every step of how a product is being manufactured and how it gets to customers. Supply chains are multi-layered, which can create problems when something goes wrong. If a certain part of a product is being damaged, it may be extremely difficult to know where and when the damage took place. Today, the supply base of many companies has become global, more outsourced and interconnected than ever before. Volatility in the economy, fluctuating commodity prices, and exchange rates add additional risks to the daily job of supply chain professionals. Due to the complexity of the supply chains today, the ranges of risks go way beyond just the financial stability of the suppliers.

Supply Chain Risks

4. Need for predictive Analysis

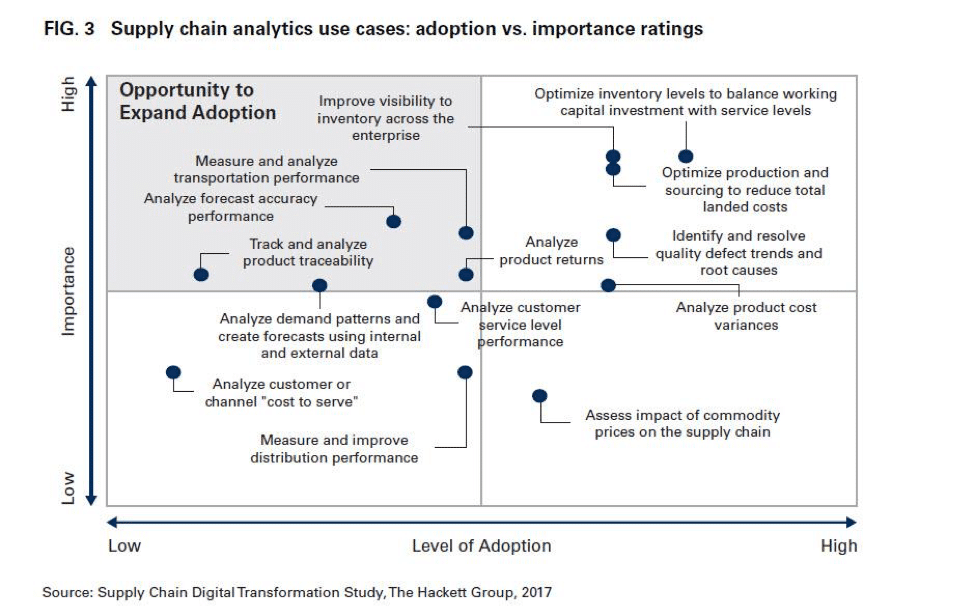

Predictive analytics is the ability to use data to predict future events and activities. This enables real-time decision making and forward planning on both strategy and performance. Machine learning that provides computers with the ability to learn and predict, has now become a part of our day-to-day life. The ability of being proactive and anticipating the future will make predictive analysis the next big thing in supply chain business intelligence. Improving forecast accuracy, optimizing transportation performance, improving product tracking & traceability and analyzing product returns are the use cases with the greatest potential for analytics growth within the supply chain. Each of these use cases and the ones that are shown in the graphic below has information and knowledge gaps that can be filled by advanced analytics.

Supply Chain Analytics Use Cases

5. Increased Inefficiencies

The supply chain consists of many stakeholders involved in getting a product into the hands of a consumer including raw material gatherers, manufacturers, transportation companies, wholesale warehouses, in-house staff, stock rooms and the teenager at the register. Traditional methods of communicating and collaborating are not efficient. It can lead to administrative mistakes, missed deadlines and damaged deliveries. To demonstrate, just in the UK alone, businesses waste about 3 hours per shipment to request and funnel data from the partners. In sum, more than 100 million hours at the annual cost of £1.5 billion is wasted.

‘Shouldn’t the solution to these inefficiencies be something like a ‘supply chain Google’?

End to end supply chain visibility provides a single platform where everything from early stage plans through final delivery can be tracked and traced in real-time on a global scale. One can locate goods as well as control the status of any item, shipment, event, partner, report, or ETA on any device updated in real time. It helps to handle disruptions, suggest alternatives, measure impacts and communicate on a massive scale avoiding any inefficiencies. Increased visibility will ensure evaluation of areas of inefficiency and in turn reduce risks of damaging products.

6. Regulatory requirements

As we know, change is constant in supply chain, new rules and regulations continue to emerge. Every industry needs to face the changing regulations. For example, within food industry, the FDA has tightened legislation around food sanitation, requiring companies to ensure food safety with the Sanitary Transport Rule; within pharmaceutical sector it is imperative to adhere to quality standards in all purchases across multiple tiers of complex supply chains. These chains have become even more complex in recent years with the increased involvement of vendors from countries across the globe, who previously played a much-limited supply role. In the EU, where public awareness and concern over environmental issues is more pronounced, they have ETS, WEEE, RoHS, and REACH and new regulations on the way, all of which keep getting more comprehensive. Furthermore, the recent protocol to Eliminate Illicit Trade in Tobacco Products requires the establishment of a global tracking and tracing regime within five years of the Protocol’s entry into force, comprising national and regional tracking and tracing systems and a global information sharing point which is only possible by adopting technologies supporting supply chain visibility.

7. Environmental Sustainability

In a report titled “The state of the sustainable supply chain” published in 2016, the global consulting firm Ernst & Young proclaimed that supply chain sustainability can no longer be ignored. The report was based on interviews with supply chain, procurement and sustainability specialists from over 70 companies around the world. Ernst & Young found that all businesses they asked (from mid-sized firms to multinationals) are taking action to adapt to geopolitical changes, raw material shortages and changing weather patterns as well as are improving the impact of their commercial activity on communities and the environment. One important aspect of supply chain sustainability is the carbon footprint. Supply chains can be responsible for up to four times the greenhouse gas emissions of a company’s direct operations. So, managing the footprint can have a significant effect on the company’s overall environmental performance. Measuring and managing the carbon footprint of your supply chain is a smart move to prepare for the future. Carbon emissions are already taxed in some places, and it could become a widespread practice.

Thus, end-to-end supply chain visibility is more important than ever. It empowers supply chain and logistics managers to make educated decisions. It helps companies to decrease the impact of disruptions on the supply chain by providing actionable data. Supply chain leaders recognize the importance of visibility as it streamlines operations, reduces business risk, increases efficiencies and enables better decision making and forecasting based on insights offered by real-time data. Thanks to the constant flow of data and insights provided by real-time cargo monitoring, companies are able to uncover the unknown, by revealing supply chain related issues. In-transit visibility creates vast opportunities for supply chain optimization.

How can Arviem help you achieve needed supply chain visibility?

Arviem specializes in IoT enabled real-time cargo tracking and monitoring services that provides in-transit visibility enabling exporters and importers to develop smarter, more efficient and responsive supply chain operations. The solution connects intermodal shipping containers, cargo, vessels, and trailers with enterprise IT systems via the use of sensors, GPS, mobile networks and a cloud-based platform. The sensors capture and transmit signals and data to provide a closer picture of the condition, geographical location and environment of goods in transit. By having the possibility to access this data at any-time from anywhere, supply chain leaders can take proactive actions and make fast and smart decisions when it comes to the unplanned, distracting events and delays in the supply chain. As the only pay-per use full-service provider of real-time cargo monitoring on the market, Arviem makes invisible supply chain operations visible by maintaining consistent data flow. Thanks to Arviem’s intelligent cargo monitoring solution, clients are empowered to make educated, well-informed operational decisions while staying in control of their cargo from its origin to its destination. To learn more click below or visit www.arviem.com