Ever wondered the conditions your goods are exposed to while they travel several modes of transport, including truck, rail, air, and sea, involving multiple hand offs? Impact, shocks and other unfavourable conditions may endanger the goods’ safety and quality while in transit causing severe financial and reputational loss to cargo owners.

As cargo is the most susceptible to damage from impact while it is in transit, monitoring its condition while it endures multiple modes of transport and multiple handoffs is critical. Data showing shock and mishandling hotspots help cargo owners to assess where and when damages happen to avoid them in the future and place accountability on the right party.

Thanks to the Internet of Things technological advancements, shocks experienced by shipments in transit can be measured in real-time. True to its capabilities, IoT enabled sensors to enrich the effectiveness of Supply Chain Operations and bring more transparency, efficiency & accountability in supply chains. With smart sensors having the power to monitor any circumstances, IoT is fulfilling the demand for certainty, transparency, and trust.

How to use real-time shock monitoring data for effective supply chain operations

Assess when and where product damage happened

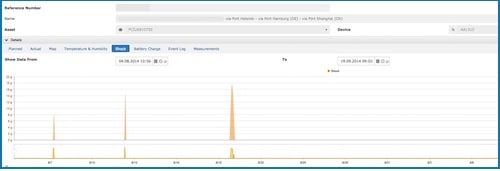

Continuous real-time monitoring data provides location and the respective shock values on the entire journey from source to destination. This increases logistics managers’ visibility into the whereabouts of impact events so that correct actions can be taken to reduce further damage.

Prove the source of cargo damage and report it on timely manner

Real-time monitoring of shocks helps you identify the damage’s root cause while the cargo is in transit. The instant notifications to all stakeholders help take proactive measures to reduce further losses if cargo has already been damaged. The cargo owner can decide on replanning the next leg or inform the cargo operator immediately.

Place accountability on the right party

The real-time monitoring data showing the shock analysis during the voyage can help establish the right accountability e.g., if carrier is liable for the damage. Reliable and relevant evidence is vital to prove the damages occurred while the cargo was in transit. It helps cargo owners put themselves in a better legal position to verify that the damage occurred during the voyage.

Expedite cargo inspections upon arrival

Prioritise cargo inspections upon arrival to the destination by focusing on shipments that have been exposed to unfavourable conditions. Additionally, with real-time data insights, cargo owner can approach their customs broker, express their concerns, and see if there’s a way to pre-clear containers to skip warehouse waiting time and prioritise clearance of potentially damaged cargo. It makes inspections more efficient, reducing the number of physical inspections needed at the terminal.

Select only reliable carriers

Evaluate your carriers on handling effectiveness. Suppose any of the issues observed in transit appear repeatedly. In that case, beneficial cargo owners can use the data to address the identified inefficiencies to respective carriers and renegotiate the terms and conditions or select only reliable carriers.

Accelerate the time needed for detecting concealed damages on arrival

Reliable, real-time data regarding shock levels could be grounds for further inspection of the shipment and provides a more proactive approach to reject a product for usage than waiting for problems to arise during equipment usage.

Accelerate claims handling process

The readily available reliable and relevant recorded data about damages that occurred in transit can serve as strong evidence with your claims to the carrier and cargo insurance provider. The detailed analytics report speeds up the claim handling process, ensuring it is a success.

Use the accumulated data to mitigate shipping risks & adapt routing and product packaging

The availability of reliable real-time shock profiles for the entire journey from source to destination helps identify trends and embrace predictive analytics to correlate the outliers with certain events during transport. The detailed report about whereabouts of damages in transit indicates damage hotspots as the basis for future planning. The cargo owner can rely on the historical data as a basis for future route and logistics planning and packaging design to mitigate shipping risks effectively and efficiently. If a particular route or carrier is more prone to in-transit disruptions, the manufacturer can opt to use a different route or different carrier going forward and accurately assess risk and allocate capital. Safety stock can be removed from low-risk areas and added to high-risk areas, enabling cost-cutting and risk reduction throughout the supply chain. With improved product handling, the unforeseen extra handling cost to prevent cargo from being lost could be reduced by 50%.

Arviem provides an IoT based visibility solution to track and monitor shocks in transit

Arviem brings visibility into supply chains using IoT technology and monitors the GPS location and cargo condition in real-time from source

Reliable real-time data that provides adequate context to enable immediate, informed actions

The enhanced supply chain visibility provided by Arviem not only supports various operational supply chain management decisions for goods-in-transit, but Arviem’s smart data analytics services also empower decision-makers to make well-funded tactical and strategic management decisions. The data empowered by machine learning algorithms help to determine baseline damage boundaries accurately, detect mishandling during transport, thus identifying product handling accountability and taking corrective actions on time. The data serve as a basis for simplified processes of insurance claims handling, risk profiling, and efficient inventory management. Thanks to Arviem’s intelligent cargo monitoring solution, clients are empowered to make educated, well-informed operational decisions while identifying improvement opportunities in overall supply chain.