The time has come, manufacturers of tobacco products moving cargo in EU member states are required to have traceability systems in place as of May 20, 2019

As tobacco is one of the most highly taxed commodities, organized crime groups find it attractive, as lucrative profits can be made through tax evasion. The illicit tobacco trade currently accounts for 10-12% of the global cigarette market which if not considered a serious problem can have several negative impacts not only on the manufacturers of tobacco products but also on public finances. In order to address this rising issue, governments are imposing new regulations on organizations dealing with tobacco products with the goal of monitoring the movement of legal tobacco products, requiring the complete traceability of the tobacco supply chain.

Tobacco Products Traceability

It has been a week since the traceability systems and security features defined in the Tobacco Products Directive 2014/40/EU (in effect as of 20 May 2019) should be in place in the Member States of the EU for cigarettes and roll-your-own products to enable authorities and citizens to verify the authenticity of tobacco products. As defined in the directive, manufacturers of tobacco products in the EU countries are under the obligation to mark every tobacco product with a unique identifier to record their movement across the entire supply chain. Looking at the timeliness of this issue, let’s look into why is traceability important for the tobacco industry.

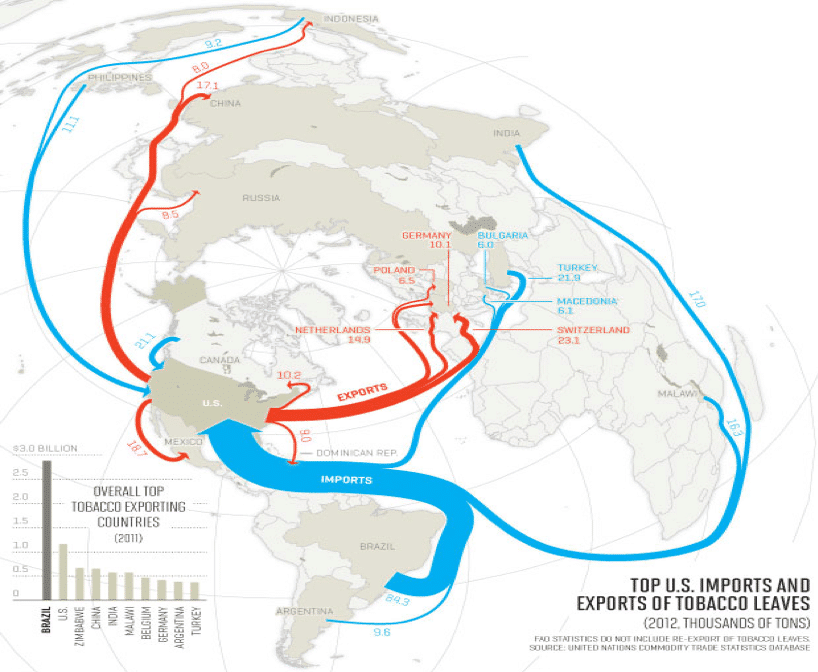

Each year about 2 million people collect, dry, and package about 8 million tons of tobacco, grown on 16,275 square miles of land to make 5 trillion cigarettes that are distributed around the world. Overall, the value of exported tobacco cigarettes rose by an average of 5.3% for all exporting countries since 2013 where worldwide shipments of cigarettes were valued at $23.9 billion. From 2016 to 2017, the value of globally exported cigarettes from all the countries has increased by 18% and is expected to rise furthermore. Among continents, European countries earned the most from tobacco cigarettes exports during 2017 with shipments amounting to $11.9 billion or 47.4% of worldwide exported cigarettes. Asia supplied 44.6% of the global total, followed by North American cigarette shippers at 4.7%. These figures clearly state the complexity of the global tobacco supply chain. An example replicating this complexity is shown in the figure below showing the complex incoming and outgoing flow of tobacco on the US market.

Tobacco leaves import & Export

With globalization, supply chains have become very complex which is required to satisfy the growing demand of end-users as well as to optimize the profitability of companies. Products can begin their lives in one part of the world, travel miles to take shape in another before getting sold in another continent to the end-user. The significant cross border trade of tobacco and related products is supported by the several actors involved in the complex processes of the supply chain, logistics, and distribution. The global nature of tobacco supply chains also makes them more vulnerable to several criminal activities for e.g. thefts, illicit trade etc. Criminals involved in such activities can infiltrate the weakest point in the supply chain and try to replace legitimate ingredients or finished products with fakes and forges, at the expense of consumers, suppliers, and manufacturers. Knowing that tobacco products are a lucrative target of criminal activities due to their high value. It is therefore vital to have a monitoring system in place to preserve the integrity of this complex and globalized supply chain.

End-to-end supply chain visibility solutions possess the ability to track and trace global containerized shipments while in transit making sure the cargo is secured from illicit activities. Thanks to the real-time data capturing capabilities of supply chain visibility solutions, manufacturers of tobacco products can get real-time information about the location, internal conditions, door opening and any other intrusions to cargo containers seamlessly when they happen. This information can be shared with all the stakeholders at the same time, helping to mitigate risks by allowing cargo owners to take corrective action, enable informed decision making well on time minimizing the global impacts of any crime that could happen while the cargo is in transit.

Why do manufacturers of tobacco products need to have a cargo monitoring/ traceability service in place?

1. Tobacco traceability is essential to combat the rising illicit trade of tobacco products

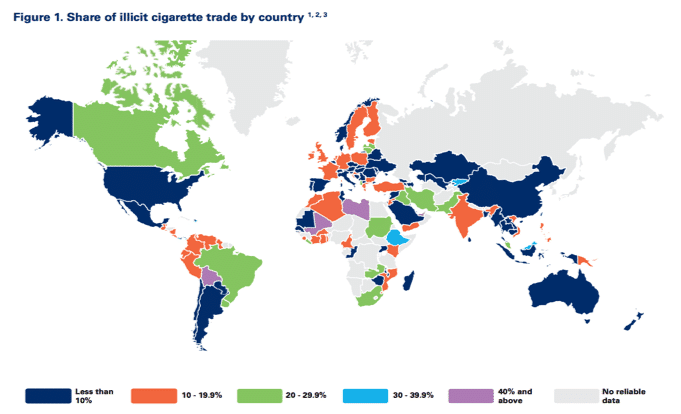

The illicit trade in tobacco products is defined by the World Health Organization’s (WHO) Framework Convention on Tobacco Control (FCTC) as “any practice or conduct prohibited by law and which relates to production, shipment, receipt, possession, distribution, sale or purchase including any practice or conduct intended to facilitate such activity”. Despite the Governments’ effort to minimize its effects, illicit tobacco trade has affected both advanced and developing economies in all continents as can be viewed in the picture below:

Illicit cigarette Trade, Source: KPMG

The illicit trade in tobacco products is both a threat to government finances and to public health. To illustrate the extent of the problem, KPMG’s Project Sun estimates that over €11 billion each year is lost in duty by EU tax administrations to illegal tobacco sales. This illegal trade also poses a serious danger to the health of an individual, both children and young adults as it increases access to cheaper tobacco products. Additionally, tobacco products from illicit activities are less likely to comply with important regulations, such as the obligation to carry combined health warnings, fueling the tobacco epidemic and undermining control policies.

Along with the substantial losses in tax and customs revenue for governments, the revenues from these illicit activities contribute to the icreased funding of international illicit trade of tobacco like smuggling (the unlawful movement of tobacco products from one jurisdiction to another, without applicable tax being paid ), counterfeiting (the illegal manufacturing of an evidently lawful and well known product, without the owner’s consent.), Bootlegging (cases where tobacco products are legally bought in one country and then transported to another with a higher tax rate), Illegal Manufacturing (cases where tobacco products are manufactured without declaration to the relevant authorities.) etc.

2. Cargo monitoring improves cargo security and reduces business risk while ensuring tobacco traceability

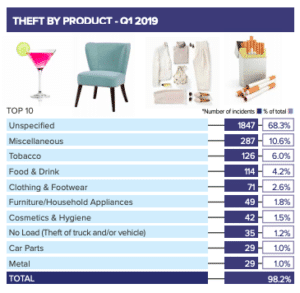

Due to the high value of shipments and the ease of reselling of stolen tobacco products, the tobacco industry faces higher in-transit theft problems than many other industries. Tobacco theft, in terms of dollar value is among the top industries for cargo theft. Cargo theft poses a serious threat to tobacco manufacturers causing not only financial loss, but also supply chain risk, and loss of potential sales. One of the reports from Tapa shows that tobacco is among the top products facing cargo theft issues.

Theft by product

Peace of mind and secure transportation is important, however for such easily resalable cargo as tobacco products, it is especially important. Making sure to not to expose cargo to danger, is crucial. High value goods, such as cigarettes demand a high level of control; hence the installation of tracking and tracing systems on shipping containers is beneficial. Using cargo monitoring technology and supply chain visibility services enables cargo owners to follow every container in real-time on a cloud-based platform reporting on predefined KPIs. Sophisticated tracking and tracing systems facilitate the establishment of operational KPIs to measure the performance of the supply chain. By installing cargo monitoring and security devices on shipping containers with communication capabilities in real-time, cargo owners can be notified in case an unauthorized door opening happens or if criminals try to intrude the shipping container by cutting its wall open.

3. The tracking and tracing of tobacco products is required by regulations

The increasing negative effects of illicit usage of tobacco encourages governments and international bodies such as the World Health Organization (WHO) to take needed action. The Protocol to Eliminate Illicit Trade in Tobacco Products often referred to as the Protocol, which was negotiated under the Framework Convention on Tobacco Control (FCTC), is one of the efforts by the parties to the WHO to combat the trade in illicit tobacco products. Furthermore, the recent protocol to Eliminate Illicit Trade in Tobacco Products requires the establishment of a global tracking and tracing regime within five years of the Protocol’s entry into force, comprising national and regional tracking and tracing systems and a global information sharing point which is only possible by adopting technologies supporting supply chain visibility. The Protocol does not exempt smaller businesses from these obligations and it is assumed that tracking and tracing will apply to all tobacco products. According to the Tobacco Products Directive 2014/40/EU, by 20 May 2019 the traceability system and the security features should be in place in the Member States for cigarettes and roll-your-own tobacco, and by 20 May 2024 for all other tobacco products (such as cigars, cigarillos, and smokeless tobacco products). Thus, all the organizations would need to traceability and supply chain visibility as one of the measures to overcome the illicit trade of tobacco products.

4. The quality of tobacco products can be ensured by monitoring the environmental conditions of cargo while in transit

Tobacco use is a major preventable cause of premature death and disease worldwide. Approximately 5.4 million people die each year due to tobacco-related illnesses – a figure expected to increase to more than 8 million a year by 2030. This death number can be further stimulated by consuming degraded quality tobacco. Quality assurance is an increasingly important aspect in the tobacco industry as tobacco products have a very short lifespan. Tobacco while in transit may be subject to various environmental changes like temperature, humidity, shock, vibrations etc. These conditions can alter the state of tobacco worsening its effect on health. This will not only cause financial damage to manufacturers (in case of recalls or damaged goods) but has negative effects on the reputation of manufacturers. Thanks to supply chain visibility and cargo monitoring solutions, environmental conditions of the tobacco can be monitored easily giving assurance to the tobacco companies that their products will be managed even when in transit, not just in terms of location, but also in terms of quality.

5. Real-time monitoring allows manufacturers to serve their clients ‘on-time in full’ ensuring positive customer experience

Gone are the days when your customer can wait for products they want. Today, everyone expects the demanded goods to be delivered immediately. To succeed in today’s hyper-accelerated, omnichannel world, businesses need to be more agile, relying on supply chain transparency to meet the customer’s demands on time and in full. Tobacco being a high consumption product, anticipating and meeting consumer demand is very much critical. Manufacturers should be in a position to tell if there is any expected delay in the shipment to their customers, enabling them to inform the customers early on. Letting the customer know the whereabouts of any shipment in transit provides an enhanced customer experience keeping customer expectations in line with reality. Additionally, unlike the milestone-based visibility solutions on the market, IoT enabled supply chain visibility solutions can help manufacturers to uncover any other disruptions in real-time. These cargo monitoring services monitor the environment of goods, such as temperature and humidity fluctuations, shocks, route diversion informing the client or the shipper of any disruptions via notifications. Knowing of disruptions, enables the stakeholders in the tobacco supply chain to be proactive and take preventive actions to mitigate these disruptions.

How can Arviem help you achieve needed supply chain visibility?

Arviem specializes in IoT enabled real-time cargo tracking and monitoring services that provide in-transit visibility enabling exporters and importers to develop smarter, more efficient and responsive supply chain operations. The solution connects intermodal shipping containers, cargo, vessels, and trailers with enterprise IT systems via the use of sensors, GPS, mobile networks and a cloud-based platform. The sensors capture and transmit signals and data to provide a closer picture of the condition, geographical location and environment of goods in transit. By having the possibility to access this data at any-time from anywhere, supply chain leaders can take proactive actions and make fast and smart decisions when it comes to the unplanned, distracting events and delays in the supply chain. As the only pay-per use full-service provider of real-time cargo monitoring on the market, Arviem makes invisible supply chain operations visible by maintaining consistent data flow. Thanks to Arviem’s intelligent cargo monitoring solution, clients are empowered to make educated, well-informed operational decisions while staying in control of their cargo from its origin to its destination. To learn more, visit www.arviem.com