In the times of the digital revolution and changing supply chain requirements, shippers need more information than ever before. Supply chain stakeholders place more importance on the need for improved visibility to identify the inbound flow of goods to satisfy higher demands and react to the unexpected. They would like to know where their goods are while in transit and in what condition at any given time. The need to capture inefficiencies, understand delays, and look at the big picture by aggregating real-time data is the force that will drive further advancements toward fully transparent supply chains. Without visibility, shippers cannot expect the fastest, safest, and importantly, the most ecological routes for their shipments. Hence, most of the companies are looking for solutions that provide freight visibility beyond monitoring the milestones tracked by their logistics service providers.

While searching for a real-time monitoring solution for their cargo, shippers will have to choose between using smart containers that are permanently equipped with a tracking device or implementing an intermodal cargo monitoring solution that provides intelligent, sensor-equipped devices that can be added to any cargo. To make a choice easier, here is a brief overview of smart containers and smart device enabled visibility solutions and how they differ.

What are smart containers?

As defined by MSC, one of the shipping lines offering smart containers, a smart container is a standard marine container permanently fitted with electronics. Smart container electronics can be built in during manufacturing, retrofitted to all types of existing containers, or embedded within the contents of the container.

What is smart device/sensor-enabled cargo monitoring?

Cargo monitoring through smart devices and sensors is one of the most independent and reliable means to trace and track the movement of goods in transit. Smart devices, also called cargo trackers, container security devices, or container tracking devices are removable, IoT enabled devices with built-in sensors that can be attached to any container. The devices can be used not only in marine containers but also to air cargo, pallets, or trucks. The independent devices can make any container smart; they can be fitted to any container before the journey begins, and doors of containers are closed.

Real-time monitoring of cargo with smart containers or smart devices is making supply chains more efficient by eliminating blind spots

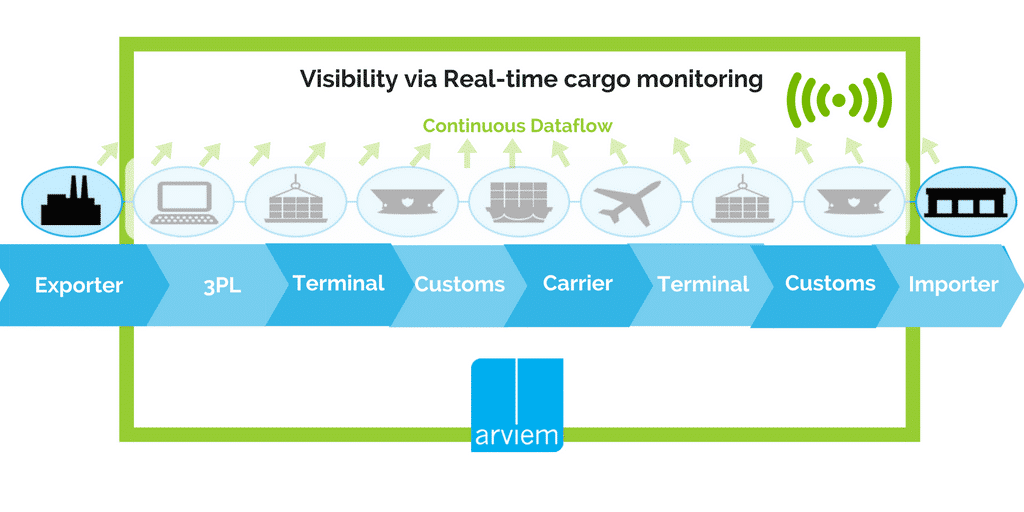

Real-time monitoring of cargo with smart containers or smart devices is taking the digital age of shipping one step further, making supply chains more transparent, reliable, agile, secure, resilient, connected, and sustainable. They eliminate milestones-based visibility from the supply chain as they provide data on the location and condition of the goods in transit. The sensor devices ride along with the cargo and provide real-time information on the geographic position as well as the state of the cargo. Depending on the type of sensors used, different parameters can be monitored throughout the whole transport process from source to destination, e.g. temperature, humidity, shock, light and door openings, etc. The generated data can be accessed via web portals or through API.

Real-time cargo monitoring, whether with smart containers or with smart device enabled containers hold promise for revolutionizing supply chains. Real-time monitoring data can be fed into analytics programs powered by AI and machine learning technology. Data analytics helps to analyze supply chain and logistics performance and streamline supply chain operations. Supply chain managers can anticipate supply chain disruptions with reliable real-time data before they occur and adjust routing accordingly. The data can even be shared easily between manufacturers and retailers to coordinate in advance of predicted delays. Thanks to improved data accuracy and accessibility, supply chain professionals are empowered to make educated, well-informed operational decisions while staying in control of their cargo from its origin to its destination. Moreover, with reliable cargo shipment data, inventory safety stocks can be reduced, dock scheduling improves, warehouse resources can be used more efficiently, and better planning can be done around shipping ETAs. This empowers decision-makers to make well-funded tactical and strategic management decisions.

However, generating and collecting smart container data is not enough to make supply chains fully “smart”. It is essential that the collected data can be easily analyzed. Additionally, it is one of the needs of shippers today to deliver independent data in a standard format for easy integration into different systems. Most shippers, BCO’s, importers and exporters favor a solution that is readily available, reliable, and deployable with on-demand requirements.

Are you confused about what makes smart container different from smart devices enabled monitoring? Here is a quick overview.

Data Ownership

Data from smart containers are owned by the shipping line or carrier who owns the smart containers and is not always easily and reliably available to shippers. Smart device enabled monitoring data is independently owned by cargo interests or shippers, making it more reliable, accurate, and timely available to all stakeholders. Easy access to independent data supports the claims handling process or helps in making strategic business decisions.

Availability

Smart containers are not easily available for larger volume or global routes. As smart containers need to be ordered from a shipping line or container leasing company when placing an order for a container, last-minute installations are not possible. Smart devices can be made available quickly and globally to monitor shipments by any carrier or even cross-carrier shipments. With device enabled monitoring, devices can be added to any container – less limiting for the shipper to fulfill monitoring needs.

Usage

Smart containers have limited market penetration – higher for refrigerated containers and lower for dry containers. Smart devices fit any ISO standard dry or reefer container, making any container a “smart container” on demand. Once the device is unmounted, the container becomes an “ordinary” container again, allowing for more efficient repositioning.

Software Integration

When using multiple carriers, software integration for smart containers is not system agnostic as different systems are required to connect to multiple data platforms or devices. Data integration is relatively easy for smart device enabled freight monitoring solutions with on-demand client requirements independent of containers, carriers, or all shipping lines.

Use cases

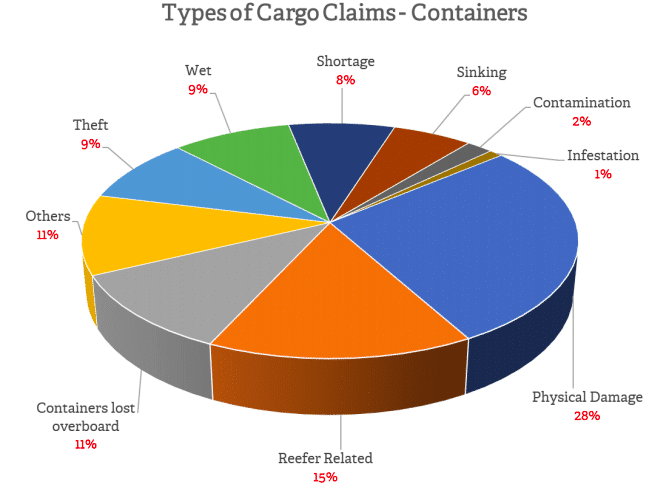

Smart containers have limited use cases. E.g., devices used cannot reliably detect door opening as they aren’t equipped with a physical or dedicated door opening sensor but rely on the light sensor to detect door status. Smart devices have on-demand use cases with more reliable sensors measuring a wider range of conditions. As smart devices are installed around the container doors, they are a reliable tool to monitor cargo security.

Roll out time

Roll-out with 100% coverage is practically not achievable for smart containers; it depends on the carrier portfolio of a customer, any roll-out to cover at least the trade lanes with available smart containers will take at least six months, rather 12+ month. Smart device monitoring can be rolled-out with 100% coverage of all containers of a large corporation within 30 days.

Economic Feasibility

The economic feasibility of the smart container solution is questionable. With logistics market fragmented as cargo owners works with multiple LSP’s and carriers, it is operationally not feasible to manage the availability of a smart container for a specific client on a specific route. As the globally available containers and their need reaches several millions, even if the companies equip 50K containers with smart containers, it accounts for 0.1% of all containers. The operational execution with smart device enabled monitoring on the other hand is easily feasible for any trade route on demand with any number of containers.

After careful consideration of both the monitoring solution’s pros and cons, we are confident that smart device monitoring is a reliable, independent, and relevant monitoring solution for any container type shipments, whether dry or reefer, on any transport mode. The solution meets all the crucial needs for end-to-end supply chain tracking and tracing, providing accurate and reliable actionable information. The smart device sensor technology folds in everything — globally available within a short span of time. It is an easy-to-use on-demand system that provides a structured information flow through simple, standardized procedures implemented and tailored to the needs of the customer. Adding to this the user-friendly analytics capabilities offered by the solution providers of smart device enabled cargo monitoring, it becomes organization-wide tool of supply chain visibility.

How can Arviem help you achieve reliable smart device enabled real-time cargo monitoring?

Arviem specializes in IoT enabled smart device based real-time cargo tracking and monitoring. Arviem offers freight visibility globally on all modes of transport as a pey per use service, requiring no investment from shippers in hardware, software or additional staff. Arviem’s real-time supply chain visibility solution makes global trade visible by monitoring the location and condition of goods in transit. The solution connects intermodal shipping containers, cargo, vessels, and trailers with enterprise IT systems via sensors, GPS, mobile networks, and a cloud-based platform. Using cloud-based infrastructure, software and analytics, Arviem turns this collected data into actionable information. Arviem leverages the collected data to offer add on services that include carbon footprint monitoring, working capital financing, supply chain analytics, supply chain risk management.