Shipping is a vital part of any supply chain, be it on road, rail, sea, or air. Ensuring safe delivery of the product into customer’s hands is essential. As shipments travel miles from their origin, often from an overseas factory, to their final destination, they are exposed to various environmental factors. Ensuring that the product arrives without damage is necessary to satisfy a customer, as well as saving costs and avoiding rework loops within the complex supply chain processes. While you attempt to take good care of the shipments in long transit, some conditions are out of human control, and accidents can happen anytime and anywhere, leading to damaged cargo. Supply chain business professionals often do not know or understand the types of cargo damage, how and why it happens, how it can be prevented to limit the loss of time, money and reduce the inherited frustration that comes along while dealing with the cargo damage claims. Here is a quick read to help you understand the most frequent types of cargo damage, how to reduce the risk, and what to do after finding out that your cargo is damaged.

Types of Cargo Damage:

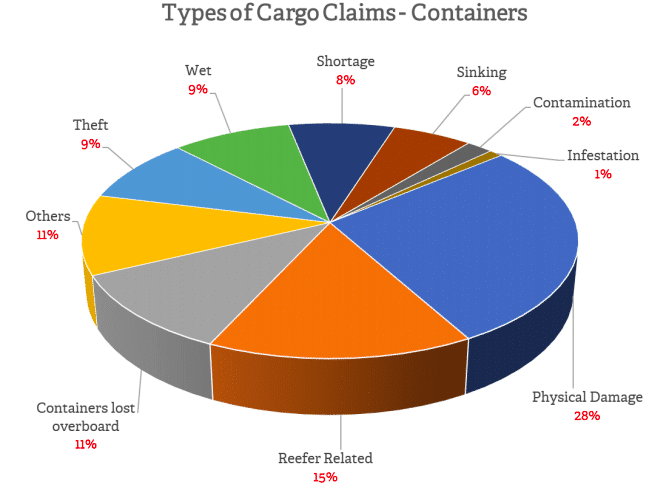

Every year, there are 1000’s of complaints registered for cargo claims associated with different kinds of cargo damages. UK P&I Club lists below cargo damages as faced on a regular basis.

Source:UK P&I Club

Physical Damage

Image Source: UK P&I Club

Wet Damage

Wet damage as the name suggests, is damage to cargo du

Image Source: UK P&I Club

Contamination Damage

Image Source: Global Recovery Services

Reefer Related Damages

Image Source: ASA Surveys

Infestation Damage

Image Source: CWA International

Measures to prevent Cargo Damage:

As a forwarder, shipper, manufacturer, or importer, it is essential that you take some definite steps to reduce the risk of damaged cargo and save financial and operational losses. Thankfully, today there are plenty of ways by which you can prevent damage to your cargo. Few of them are listed below:

- Use the correct type of container for shipping respective products. E.g. heavy cargo needs a container designed to carry heavy items.

- Ensure that the right lashings and dunnage material are used within the container to restrict the movement of cargo.

- Ensure that the incompatible products are not mixed in the container e.g., mixing clothing with chemicals.

- When shipping cargo susceptible to wet damage, make sure the correct route is chosen. Climates with high humidity, for example, could affect the cargo, and condensation could create water damage. Before shipment, ensure all doors of the container are well sealed and that all rubber gaskets are present.

- Frozen cargoes should be checked for dehydration, desiccation, fluid migration, odors, black spot, color and flavor changes, and should also be examined for signs of any upward temperature deviation and subsequent re-freezing

- Ensure you use technology-enabled solutions to know real-time updates about the location and condition of your cargo in transit to avoid any damage and take proactive measures to reduce further losses in case cargo has already been damaged. Use data from these technology-enabled services to accelerate your claims handling process.

How can Arviem help you achieve damage control and reduce financial losses?

Arviem takes pride in its real-time cargo tracking and monitoring services and does its utmost to ensure that the cargo in transit arrives on time and in good condition. IoT enabled Arviem’s solution helps to receive advanced insights and live alerts on accurate location and condition of cargo, be it high-value or condition-sensitive cargo (chemicals, perishables, electronics) and helps you to take proactive measures well before time. Arviem’s cargo condition monitoring services are of significant value when it comes to reducing cargo damages. By having the possibility to access the data at any time from anywhere, supply chain leaders can take proactive actions and make fast and smart decisions when it comes to the unplanned, distracting events and delays in the supply chain. Moreover, the real-time data about the location and condition of the cargo can be used in the claims handling process giving you assurance about easy and fast claims approval.

What to do after damage to your goods has occurred in-transit?

Make sure you document the damage with photos and file a cargo damage claim. Understand the cargo claim process to be sure that you get financial aid if your shipment is damaged during transit.

Join our webinar to learn how you can accelerate your claims handling process by relying on independent data describing the environmental conditions the goods have been exposed to during their journey.